lathe machining, lathe turning, machining mill, cnc lathe process

Features

1, low-frequency torque, stable output, high-performance vector control, fast dynamic torque response, steady speed and high precision, strong anti-interference ability.

2. The five tools and two tail shafts processed by the automatic lathe can work simultaneously in the machining process. Therefore, the speed of automatic machine tools is 4 to 6 times faster than that of ordinary lathes.

3. Automatic lathe processing complex parts can be synchronized: Cylindrical, spherical, conical, arcuate, stepped, slotted, drilled, tapped, die-cut, embossed, cut, and other processing, all processing operations can be completed in one go, with extremely high processing accuracy. without manual operation, automatic feeding is fully automated, and one person can see more than one. At the same time, it can also use the milling device to process the external thread, completely solve the problem that the die is difficult to process, and can process the double-headed thread.

4. prkpiece to achieve high accuracy, according to the workpiece processing process can be installed more than 10 kinds of knives. Two-axis device; The main shaft uses electromagnetic clutch to drive the tapping spindle. The high-speed rotation and the mechanical spindle are used for tapping in the same direction. Two-axis processing can be exchanged, reaming, attacking the internal and external teeth can be processed at the same time.

5. The structure is precise, and the cam is used to control the production. One revolution of the cam completes the processing of one part. Cam rotation speed 10 to 36 rpm, can be adjusted according to different processing parts, the fastest can be processed 36 parts per minute.

Technology

(1) High precision

The performance of CNC lathe processing control system has been continuously improved, the mechanical structure has been continuously improved, and the precision of machine tools has been increasingly improved.

(2) High efficiency

With the application of new tool materials and the perfection of the machine tool structure, the machining efficiency, spindle speed, and transmission power of CNC lathe machining are continuously improved, which greatly shortens the time for new CNC lathe machining.

(3) High flexibility

CNC lathe processing is highly flexible, suitable for more than 70% of the multi-variety, small-volume parts of automatic processing.

(4) High reliability

With the improvement of the performance of numerical control systems, the trouble-free time of CNC machine tools has been shortened.

(5) Strong process capability

It can be used for roughing and finishing, and can complete all or most of the steps in a single setup.

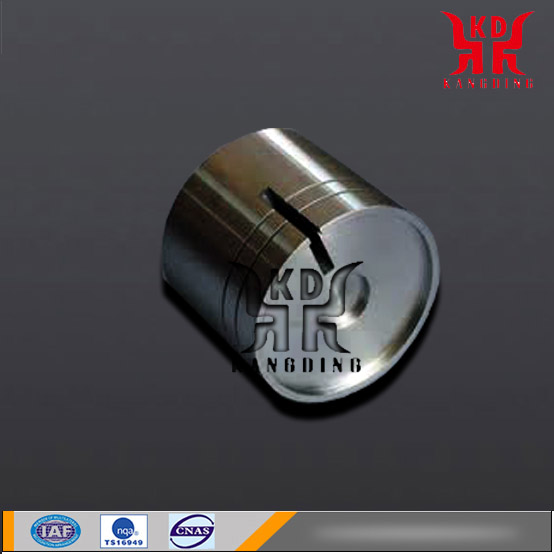

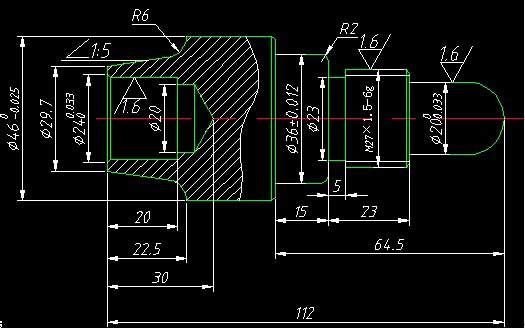

(6) Analysis of parts (below):

The surface of the part is composed of a cylinder, a straight arc, an inverse arc, a cone, a groove, a thread, a hole, and the like. The dimensioning is complete. The blank is 45# steel Φ50mm×120mm. Heat treatment: Modulation treatment, HRC25-35 has no hardness requirement.

Accuracy and tolerance standards

Turning accuracy refers to the extent to which the actual geometrical parameters (size, shape, and position) of the part are consistent with the ideal geometrical parameters. The difference between them is called the machining error. The size of the machining error reflects the level of machining accuracy. The larger the error is, the lower the machining accuracy is, and the smaller the error is, the higher the machining accuracy is. Kangding strict implementation of all products: GB/T1184-1996, GB T 25372-2010, GB/T1804-2000

(1) Linear dimensions: for example outer dimensions, inner dimensions, step dimensions, diameters, radii, distances, rounding radius and chamfer height;

(2) Angle dimensions: Include angle dimensions that do not normally indicate angle values, such as right angles (90°); linear and angular dimensions of the machined assembly.

Turning parts linear dimension limit deviation value

| Tolerance level | 0~3 | >3~6 | >6~30 | >30~120 | >120~400 | >400~1000 | >1000~2000 | >2000 |

| Precision (f) | ±0.01 | ±0.02 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | — |

| medium (m) | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2.0 |

| Rough (c) | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2.0 | ±3.0 | ±4.0 |

| Thickest (v) | — | ±0.5 | ±1.0 | ±1.5 | ±2.5 | ±4.0 | ±6.0 | ±8.0 |

Turning parts rounding radius and height dimensions of the chamfer limit deviation value

| Tolerance level | 0~3 | 3~6 | >6~30 | >30 |

| Precision (f) | ±0.2 | ±0.5 | ±1.0 | ±2.0 |

| medium (m) | ||||

| Rough (c) | ±0.4 | ±1.0 | ±2.0 | ±4.0 |

| Thickest (v) |

Limit deviation value of angular dimensions of turned parts

| Tolerance level | 0~10 | >10~50 | >50~120 | 120~400 | >400 |

| Precision (f) | ±1° | ±30′ | ±20′ | ±10′ | ±5′ |

| medium (m) | |||||

| Rough (c) | ±1°30′ | ±1° | ±30′ | ±15′ | ±10′ |

| Thickest (v) | ±3° | ±2° | ±1° | ±30′ | ±20′ |

Processing materials

CNC turning machining is a high-tech processing method for precision metal parts. Can process various types of materials, such as 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, plastic, acrylic, POM, UHWM and other raw materials, can be processed into square, round combination Complex structural parts.

1. Stainless Steel (SUS)

SUS301 (17Cr-7Ni) stainless steel can obtain high strength after cold working. SUS301 stainless steel is used in railway vehicles, belt conveyors, bolts and nuts, springs, etc.

SUS304 ---- SUS304 is 18/8 stainless steel. GB brand is 0Cr18Ni9 (new standard 06cr19ni10), 304 stainless steel is widely used for making corrosion resistant and formability equipment and components because of its good heat resistance.

2, carbon steel ----S50C, SK5, SK7

Features: Good stability, heat treatable.

S50C, SK5, SK7 are mainly used in the COOLER MASTER radiator backplane.

3. Copper (CU)

Oxygen-Free Copper (OFCU) ----C1020----O, 1/4H, 1/2H, H Characteristics: Electrical conductivity, thermal conductivity, extrusion processability, corrosion resistance, and heat resistance are all good.

4, Aluminum (AL)

4.1. Aluminum Alloy (A1070)----O, H14, H18

Features: High thermal conductivity, formability, corrosion resistance, good anodic treatment.

Uses: Hose, capacitors, knobs, cosmetics accessories, accessories, reflectors, nameplate frames, lighting fixtures. 6.2. Aluminum alloy (A1050) ---- O, H14, H16, H18 Features: Formability, good corrosion resistance.

4,2 COOLER MASTER almost all aluminum radiators FIN and COVER use A1050.

4.3. Aluminum alloy (A1100) ---- O, H12, H14, H16, H18 Features: Formability, corrosion resistance thermal conductivity, good anodic properties.

4.4. Aluminum Alloy (A3003) ---- O, H32, H34, H36, H38 Features: Good corrosion resistance in forming and forming is higher than 1100.

4.5. Aluminum alloy (A3004) ----O, H32, H34, H36, H38 Features: Higher strength than 3003, good deep-drawing property, good corrosion resistance, high temperature resistance. Uses: beverage cans, pressure vessels, lamp holders.

4.6. Aluminum Alloy (A5052) ----O, H32, H34, H36, H38H

4.7. Aluminum alloy (A6063-T5) COOLER MASTER part of the aluminum extrusion, SKIVE FIN heat sink, etc. use this material.

Programming design

The CNC machine tool automatically processes the machined parts according to a pre-programmed machining program: (Common instructions are as follows)

N10 G50 X50 Z100 ; Positioning the workpiece coordinate system with tool change points

N20 M3 S560 ; Start Spindle

N30 T0101 ; Change No. 1 knife

N40 G0 X25 Z2 ; Quickly move to the processing starting point

N50 G71 U0.8 R0.5 ; Execute cylindrical roughing cycle

N60 G71 P70 Q140 U0.5 W0.2 F100 ; allowance X0.5 Z0.2, feed 100 mm/min

N70 G0 X0 ; Contour processing start line

N80 G1 Z0 F30 ; Finishing feed 30

N90 G3 X10 Z-5 R5 ; Retract and leave the workpiece

N100 G1 Z-15 ; Machining R15 arc with right angle of 4

N110 X18 W-10 ; Processing Φ26 outer circle

N120 W-7; inverted 3×45° right angle

N130 X21 ; Spindle rotating at 400r/min

N140 X23 Z-33 ; Spindle stop, main program end and reset

N150 Z-45 ; Contour finishing line

N160 G70 P70 Q140 ; Perform finishing cycle

N170 G0 X50 Z100 ; Tool change point

N180 T0404 ; Change knife No. 4

N190 G0 X27 Z-40.1 ; Positioning cutting start point, leaving 0.1mm margin

N200 G1 X12 F15 ; Processing R15 arc segment

N210 G0 X25 ;

N220 Z-40 ;

N230 G1 X0 F10 ; Cutting off, feed rate 10mm/min

N240 G0 X50 ;

N250 Z100 M5 ;Return tool point, stop spindle

N260 T0100 ; Return to standard knife

N270 M30 ; End procedure

Device

Lathes, reamers, reamers, taps, dies and knurling tools can also be used for machining on turning . Including cylindrical processing equipment, inner hole processing equipment, plane and groove processing equipment, gear processing equipment, thread processing equipment, box processing equipment ... and so on.

Turning processing is generally processed at room temperature, and does not cause changes in the chemical or physical phase of the workpiece. It is called cold processing.

Kang Dingxin has a full range of processing equipment: lathes, boring machines, milling machines, planers, grinding machines, drilling machines, CNC machine tools.

All automatic lathes use Taiwan MY. Knife cutter is based on 20 and 15 models. Imported five axis Walk the heart Precision machining parts

Feeder: Swiss brand Ai Si Division, 15 cam machine small parts production, car, pressure, drilling, tapping, Taiwan-made 32-type automatic lathes: (main shaft 32MM) ultra-fast processing speed.

Kangding automatic lathe processing workshop

Quote

Turning Processing Parts Price = Raw Material Cost - Waste Revenue + Machine Cost + Labor Cost + Management Fee + Profit + Packaging Cost + Shipping Cost + Mold Amortization Charge + Tax

J16t: (7.2 yuan/hour)

J25t: (9.8 yuan/hour)

J40t: (13.1 yuan/hour)

Milling: 20 to 35 yuan/hour

CNC car J63t: (20 to 30 yuan/hour)

J80t: (18.3 yuan/hour)

J100t: (19.2 yuan/hour)

J160t: (22.5 yuan/hour)

Outer ground grinding: Broaching (20 yuan/hour)

High-speed rushed 100T below each 0.03 ~ 0.10 yuan

Gear 315t: (30.7 yuan/hour)

Gear 175t: (25 yuan/hour

Shearer: (17.1 yuan/hour)

Car C616 C7620: (12~14 yuan/hour)

Ordinary tapping: (5.21 yuan/hour)

Radial drill: 13 yuan/hour

Welding 2: 5 yuan / hour

Quenching steel: 4 yuan/kg, alloy steel 10 yuan/kg

Carbide: 700 yuan/kg

EDM: 15 yuan/hour

Argon arc welding: (50 yuan / hour with 70 yuan / bottle of argon)

Wire cutting: 7 PCT/mm2

Turning Processing Parts Price = Raw Material Cost - Waste Revenue + Machine Cost + Labor Cost + Management Fee + Profit + Packaging Cost + Shipping Cost + Mold Amortization Charge + Tax

J16t: (7.2 yuan/hour)

J25t: (9.8 yuan/hour)

J40t: (13.1 yuan/hour)

Milling: 20 to 35 yuan/hour

CNC car J63t: (20 to 30 yuan/hour)

J80t: (18.3 yuan/hour)

J100t: (19.2 yuan/hour)

J160t: (22.5 yuan/hour)

Outer ground grinding: Broaching (20 yuan/hour)

High-speed rushed 100T below each 0.03 ~ 0.10 yuan

Gear 315t: (30.7 yuan/hour)

Gear 175t: (25 yuan/hour

Shearer: (17.1 yuan/hour)

Car C616 C7620: (12~14 yuan/hour)

Ordinary tapping: (5.21 yuan/hour)

Radial drill: 13 yuan/hour

Welding 2: 5 yuan / hour

Quenching steel: 4 yuan/kg, alloy steel 10 yuan/kg

Carbide: 700 yuan/kg

EDM: 15 yuan/hour

Argon arc welding: (50 yuan / hour with 70 yuan / bottle of argon)

Wire cutting: 7 PCT/mm2

PREVIOUS:NONE

NEXT:Shaft Machining

NEXT:Shaft Machining